Silicone cases

Silicone cases are generally made of rubber, soft and flexible, and are often used to protect electronic digital products from accidental drops or wear and tear.

Chinese Name

硅胶套

English Name

silicone cases

Alias

Silicone cases

Chemical formula

mSiO2-nH2O

Molecular weight

60.08

Water solubility

Insoluble in water

Contents

- 1 History of development

- 2 Applications

- 3 Effects

- 4 Colors

- 5 Selection of silicone

- 6 Production process

- 7 Functioning characteristics

- 8 Innovative functions

- 9 Selection

- 10 How to produce

- 11 Market Prospects

Silicone cases Development History

From silent to hot, cell phones became popular in the early 90s, when they were called “Big Brother.” With the rapid development of communication technology, “Big Brother” became more and more slim, beautiful, and functional. More and more powerful. Nowadays, cell phones have become popular and necessary for life, a must-have thing to go out. With the popularity of cell phones, cell phone accessories have also flourished; especially worth mentioning is the changing development of cell phone covers, from practical to fashionable, from heavy to thin, and from simple to retro, constantly creating their own fashion culture.

In today’s electronic digital products accessories market silicone protective cases dazzling, become a beautiful landscape. When the cell phone first came out, the initial function of the protective case is relatively single: to protect the phone, cell phone, and easy to carry. The “Big Brother” silicone case is very monotonous, “Big Brother” wrapped like a baby, lacks aesthetics. At the end of the 90s, those who owned cell phones were generally mature men, and it was popular to hang the phone on a leather belt, which was very convenient to access. At that time, the basic protective cover is made of leather material, showing a mature atmosphere, but the style and appearance of the lack of innovation, of course, the phone did not have the popularity of today.

After 2000, the price of cell phones fell, college and high school students began to popularize cell phones, and cell phones became the “three prepared items.” People no longer like to hang the phone on their waist, as if that looks old-fashioned. At this time, lightweight cotton, velvet, and silk cases appeared one after another. With more and more materials and styles of silicone cases, the issues took a diversified path, but the cell phone silicone case market was not hot. After 2007, smartphones started to impact, and with the arrival of the 3G era, the development of cell phone intelligence has become an irreversible trend worldwide. The demand for high-end smartphones is increasing, especially since Apple cell phones have exploded in the market, silicone cell phone accessories are rising again, and professional digital accessories brands are being created in China. OYI Gifts focuses on the field of phone accessories, its customized cell phone cases up to a dozen series, and hundreds of styles. From a single image to 3D graphics, from Scottish plaid to natural dewdrop, various elements decorate the silicone cases. OYI Gifts uses modern advanced technology and fashion concept to create new and personalized cell phone silicone cases.

It can be seen that the silicone cases has got rid of the single protection; it is more to pursue fashion, express personality, and create more creativity and novelty on this small carrier. Today, when buying silicone cases for cell phones, perhaps consider how to match the bag to look good. It began to decorate our lives, the future of cell phone silicone cases I believe more is to tell the fashion.

Applications

Silicone sleeves are silicone products in the category of silicone gifts; silicone sleeves are very widely used, commonly used in Mp3/Mp4 players, iPods, PDAs, cell phones, PSPs, digital cameras, GPS, and other more common personal consumer electronics, the primary role is to protect electronic products from drops and scratches.

The protective cover material is soft, and flexible to protect the device, according to the degree of thickness of the silicone cover, with a certain degree of cushioning, if thick If the consistency is sufficient, coupled with a reasonable structural design, the

Can make the protected products with anti-drop function (both normal use states, such as accidentally slipping to the ground, can effectively avoid the machine and the basis for collision damage)

The corresponding silicone cover we call the Mp3 silicone cover, Mp4 silicone cover, iPod silicone cover, PDA silicone cover, cell phone silicone cover, PSP silicone cover, digital camera silicone cover, and GPS silicone cover.

Function

1、Prevent complex objects from leaving scratches on the screen or body of the phone.

2, can be printed in a variety of colors, beautiful, generous.

3, to prevent nails from contact with the keys for a long time scratching, and abrasion, there is a role in protecting the screen and keys.

4, the role of anti-slip; and feel the quality is perfect.

5, Apple phone cover, but also has the role of enhancing the signal. Some cell phone shells and metal contact with the formation of magnetic fields interfere with the cell phone signal; to the phone on the insulated phone cover, you can enhance the movement.

Material

The material of silicone cover is a highly active adsorbent material, which is amorphous and has the chemical formula mSiO2-nH2O. It is insoluble in water and any solvent, non-toxic and tasteless, chemically stable, and does not react with any substance except strong alkali and hydrofluoric acid. The chemical composition and physical structure of silica gel determine that it has many characteristics that are difficult to be replaced by other similar materials: high adsorption performance, good thermal stability, stable chemical properties, high mechanical strength, etc.

Color

The color of the silicone cover is formulated by adding a specific ratio of color paste to the raw material of silicone. Theoretically, the Pantone color card colors can be deployed, but in practice, there will be a certain degree of color difference.

Choosing silicone

Silicone cases are the most familiar type of phone cover. It has a soft texture and slightly slippery feel and has been popular in the market for years. It has developed from a crude ground-floor product to a well-made personalized brand with a consistently leading market share. Because of their excellent cost performance, silicone covers became popular and favored by many people when Phones and Airpods were hot later on. There are two kinds of silicone covers, one is organic silicone, and the other is inorganic silicone. The silicone covers for cell phones on the market belong to the former. Organic silicone has many advantages, such as high-temperature resistance, martial resistance (not afraid of ultraviolet light or ozone decomposition), sound insulation, and stable material (will not change with the animal body). Besides, people choose silicone covers because of their good hand feel: some of the phones with rugged keyboards will be improved after the silicone cover is put on. And it can absorb the impact brought by some knocks on the phone, thus reducing the damage to the phone. In addition, the waterproof performance of the silicone cover is better, which has also become its most significant selling point. Although the advantages of the silicone cases are a lot, the price is also low. But there are still shortcomings due to poor breathability; long-term wear will lead to heat accumulation in the phone body. Especially some of the heat is relatively highly intelligent phones; it is not recommended that users use it. In addition, the silicone cover itself has a slight stickiness, after using a period, will gather and absorb a lot of dust on the phone, in the long run, but not conducive to the beauty of the phone, and the original purpose of protecting the phone. In addition to the above precautions, the purchase of cell phone silicone covers is also worth paying attention to one or two. There is a wide range of silicone covers, and they can be found everywhere on the ground, in supermarkets, and in the cell phone market. But by no means buy the correct phone model. Everything is fine, the price of the cheap silicone cover is often poor quality, either not on the cover, or the position is not symmetrical. Sound quality is excellent; adequate protection is the king. Most of the former regular silicone covers are priced at just over a dozen dollars, so there is no need to lose a lot for the sake of cheap.

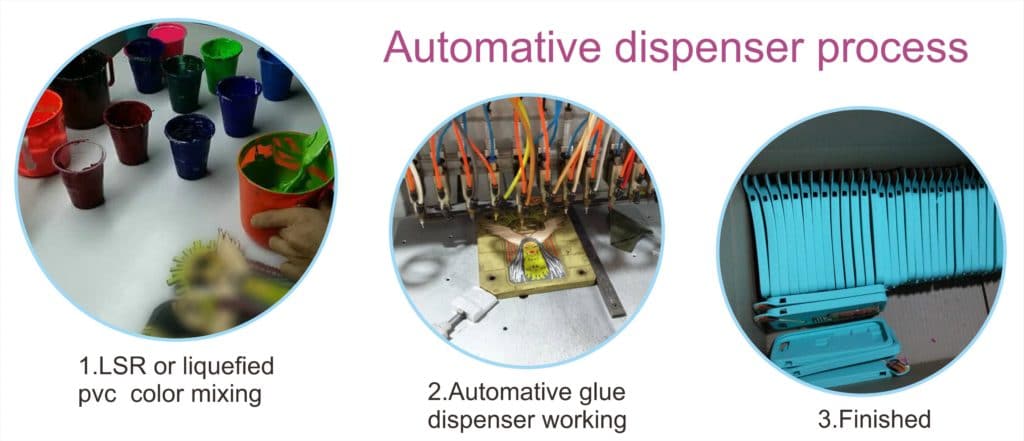

Production Process

The silicone case is a silicone rubber product produced by high-temperature vulcanized rubber as the primary raw material through the molding process.

Ordinary silicone cases need to go through the following processes.

First, Raw material preparation (also called rubber refining, material preparation, etc.).

Including the mixing of raw rubber, color matching, weight calculation of raw materials, etc.

The second is vulcanization (also called oil pressure molding).

The use of high-pressure vulcanization equipment after high-temperature vulcanization, so that the silicone raw materials are into a solid molding

Third, the peak (also known as processing, deburring, etc.).

The silicone cover products from the mold will be taken off with some useless edges and hole chips, which need to be removed; in the industry, this process is entirely done by hand; some factories also use punching machines to complete.

Four, screen printing

This process is only used in some silicone cover products with patterns on the surface of the silicone cover, such as black cell phone silicone cover; to make the user convenient to operate the keys, it is often necessary to screen print the characters corresponding to the cell phone keyboard in the corresponding position.

- Surface treatment

Surface treatment, including dust removal by air gun.

Sixth, oil spraying

Silicone products in their normal state can adsorb dust in the air and have a certain stickiness. Spraying a thin layer of hand oil on the surface of the silicone cover can both prevent dust and make the hand feel guaranteed.

Seven, other

Other processes include some additional functions given by the businessman to the silicone cases, such as drip glue, laser engraving, P+R synthesis, optimal packaging, and assembly with other materials and components.

Features

As an accessory for electronic products, the primary role of the silicone case is to protect the surface of the product from scratches and dirt.

We all know that most handheld electronic equipment shells, to pursue the beauty of the surface, the designed most of hard mirror plastic shells or metal shells, and in daily use, often with clothing desks or other material objects for contact friction, the surface will not take long to produce scratches, severe or even decolorization, so that a new machine will soon become old, a few hundred dollars more than a thousand dollars of Equipment, due to wear and tear on the appearance of the value will be significantly reduced, so careful consumers will think of many ways to protect their machines, before the emergence of silicone covers, careful manufacturers will give these devices with a leather cover or cloth cover.

But, due to the inconvenience of use, these accessories are often set aside by the user because your regular use of the process, if a holster or cloth cover, often affects the normal operation, especially cell phones such as handheld devices with button operation and silicone covers happen to have a leather cover. The cloth cover does not have these characteristics.

The silicone material is transparent, soft, flexible, and completely set on the machine, but it also will not affect the control of the device. In addition, the silicone cover is designed to be molded, so the manufacturer will give full consideration to the maneuverability to ensure that the silicone cover on the machine without the leather cover, or cloth cover, is often taken off from the device and then installed, which significantly facilitates the user, in addition, the material used in the silicone cover has a very good inert, the average state will not react with any other acid and alkaline products, and waterproof, high-temperature resistance, heat insulation. Therefore, silicone cases are a suitable protection device for handheld electronic devices, such as cell phones, tablet PCs, MP4, etc.

Innovative features

With the design innovation of silicone cases developers and the exploration and application of silicone product technology by silicone case manufacturers, silicone cases have the essential protection function. They have more artistic performance, and we have seen the emergence of many very innovative silicone cases products in the past, especially in the iPod silicone cover, various cartoon shape silicone covers, colorful silicone covers, printing pattern silicone covers, etc. Ultimately, these innovations have been accomplished through the following process innovations. -Innovation in appearance structure Innovation in mold design to make the product unique shapes innovation in material combination Innovation in surface pattern.

Selection

The purchase of silicone sleeves should be distinguished from the following aspects.

Material: divided into pure silicone and ordinary rubber, pure silicone toughness, force stretching will not turn white, and regular silicone is easy to break, gently pull the rubber will be white, indicating that there is added value of cheap silicon powder inside, the second best.

Feel: good feel smooth, poor feel sticky.

Appearance: good color uniformity, insufficient surface roughness, varying shades of color, and even impurities can be observed.

Taste: silicone has more or less odor. Poor silicone taste is robust and unpleasant.

Second: the mold is different. The reasonable and acceptable degree of mold design lays the quality and ease of using the finished silicone sets.

Other: silicone thickness, post-processing, etc., will also affect the cost of silicone sleeves.

Generally speaking, the thicker the silicone cover, the higher the cost. But not the more expansive, the better, or the thinner, the worse. For example, thicker ones may affect the feel/operation, and thinner ones are snugger.

Post-processing, including dust treatment, raw edge trimming, etc.

How to produce

First, the preparation of silicone raw materials includes mixing natural rubber, color starting, weight calculation of raw materials, and other work contents.

Second, mold forming, the production of silicone cover products is undoubtedly the need for a mold to produce products, where the market is to have a silicone cover mold or make a good mold, and then through the mold to make the silicone cover has a preliminary has been shaped products.

Third, the product trimming, product trimming because the mold forming link will undoubtedly stick to some product table edge, need to be removed manually.

Four, the screen printing process screen printing is to add some patterns or characters for the surface of the silicone cover, facilitates the user to operate the keys, and increases the product’s aesthetics.

Market prospects

The silicone cake mold’s low-carbon and environmental protection characteristics fit well with the consensus sustainable development strategy and the construction of an environmentally friendly society. Coupled with the many excellent features, it will undoubtedly gain a larger market soon. The attractive characteristics of the silicone cake mold align with the consensus sustainable development strategy and the construction of an environmentally friendly society. The market will perform well in the future.

The superior performance, coupled with the fact that silicone is a non-petroleum product and does not depend on increasingly scarce petroleum resources, makes silicone products become a substitute for similar plastic products has been the trend. In contrast, silicone products can be applied to many plastic products that can not do the field of use, such as baby pacifiers, silicone kitchenware, etc. The application prospects are extensive. All of our products have passed the FDA certification, SGS certification, and LFGB certification in Europe so that they can enter the market without any obstacles. Our products are sold in Tianhong, Junshang, China Resources Vanguard, and other large shopping malls, covering more than 60 branches, and exported to the United States, the United Kingdom, Germany, Russia, the Netherlands, Spain, Australia, Denmark, Italy, Hungary, Switzerland, Sweden, Hong Kong, and other countries and regions. Switzerland, Sweden, Hong Kong, and other countries and areas have been generally recognized and praised by most consumers. Silicone lifestyle products have become the bright landscape of people’s fashion lives.