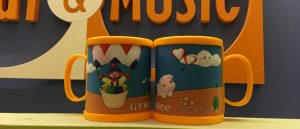

Cartoon 3D Custom Plastic Mugs

Features:

1. Material: Soft PVC wrap with ABS OR PP inner layer

2. Size: Standard size or per your request.

3. Processing: Injection of soft PVC

4. Different designs available, multi-pictures available

5. Various styles and colors available

6. Packing with an OPP bag or can be customized

7. MOQ: 3000-5000PCS.

*ALL REGISTERED CHARACTERS/LOGOS/TRADEMARKS ARE SHOWN FOR REFERENCE PURPOSES ONLY.

The mug is good for children to drink, advertising gifts, promotion gifts, souvenirs, etc.

What is plastic? (Custom plastic mugs' material)

Plastic is a type of synthetic or man-made polymer; similar in many ways to natural resins found in trees and other plants. Webster’s Dictionary defines polymers as any of various complex organic compounds produced by polymerization, capable of being molded, extruded, cast into various shapes and films, or drawn into filaments and then used as textile fibers.

Why do we use Soft PVC + Custom Plastic Mugs?

Unbreakable gentle percent rubber cover custom plastic mugs are bright-colored, have excellent touch feeling, and 3D alleviation results make them welcomed by youngsters. The material of the outer floor is eco-friendly PVC and the inside body is ABS; respectively adopts gentle percent craft and injection craft. The custom plastic mug wrapped with 2D or 3D-designed soft PVC material and high rack dishwasher is trustworthy. The common dimension for smooth P.C. Section is set W.237mm x H.78mm. Its personalized rubber cover custom plastic mugs are additionally prime rack dishwasher reliable.

Firstly, the custom colorful design, fashion, and unique,3D effect touch feel, kids and young people love it very much, it suits their personality and trundling.

Secondly, promotion, advertising your brand or company, custom your company logo on it, and the logo permanent with the custom plastic mugs, all of the people use the cup every day, which adds a huge amount of exposure to your company. The small cost and big exposure is a very cost-effective thing

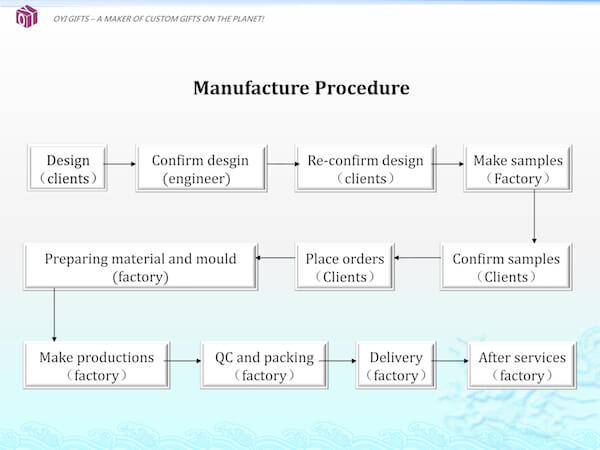

Production Process:

More Articles:

- 10 Fun Ideas for Plastic Mugs for kids

- Key to successful marketing: The right promotional products manufacturers

- Ordering promotional products from China: Cost-effective quality is always assured

- Professional Corporate Gift Customization: It’s what leaves a lasting impression

- Custom gift ideas for everyone – You and your recipients will just love them!

- Do you know more information about Creative Gifts?